EngineeringPosition:Home » Engineering

The high-quality mold begins with high-quality design. Our design team by a number of talented designers and more than 20 years of experience in mold design management. Meanwhile, we are equipped with the most state-of –the –art hardware and design software. Our design department has sufficient capacity to your wonderful ideas into perfect product.

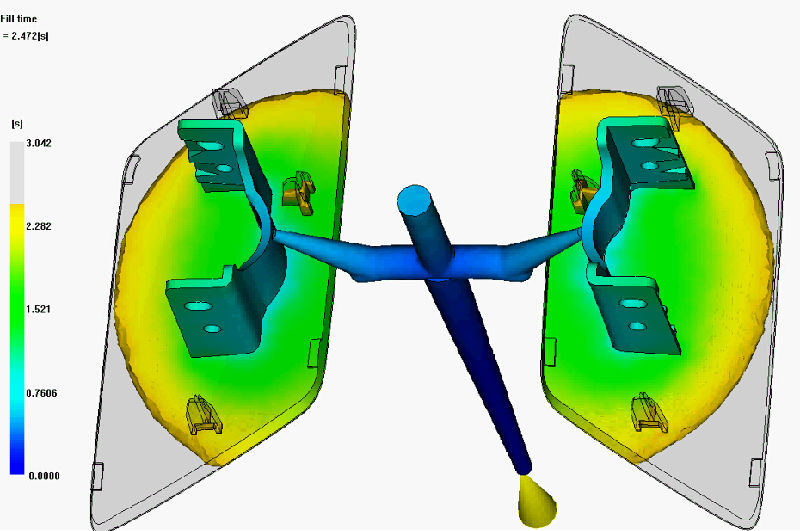

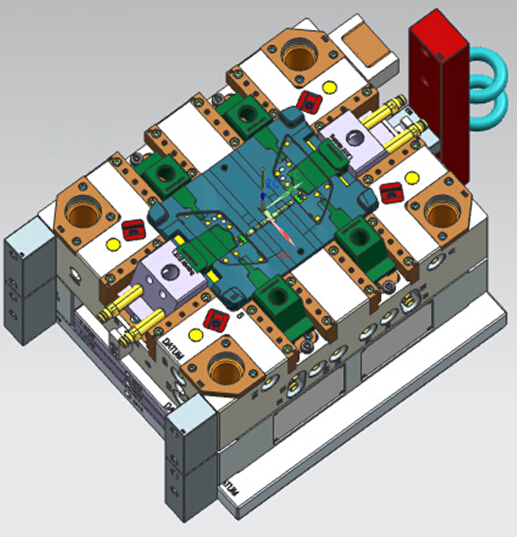

In accordance with international standards, such as EDM, HASCO, DAIDO or customer-specific standards, we guarantee each mold design can run at a specified country or region. We are able to be designed according to customer DXF, DWG, PRT, SAT, IGES, STEP and X_T format drawings. With professional CAD/CAM/CAE software, we can make the product design, mold design and CNC machining seamless connection, thus ensuring high-precision molds and production of high efficiency.

|

|

|

Analysis from the production to the mold assembly diagram to the assessment of the mold parts diagram, each mold we are organizing three project engineers, designers, mold making and technical director to participate in the project review meetings to ensure that all relevant personnel can accurately understand project requirements and design of high quality, so we designed each mold can be reliably and efficiently run automatically and maintenance fees are minimized.

We are proficient in the design of BMC mold MUD mold, hot runner mould and die casting design and experienced in the designing INCOE, EWIKON, SYNVENTIVE , MOLDMASTER, YUDO and famous brand hot runner mold etc. We have designed molds with up to 16 hot nozzles, meanwhile, we are skillful in applying famous standard fitting, such as HASCO,DME PARTKER, STAUBLIT etc.